Challenge

Addressing High-Volume, High-Risk Shading

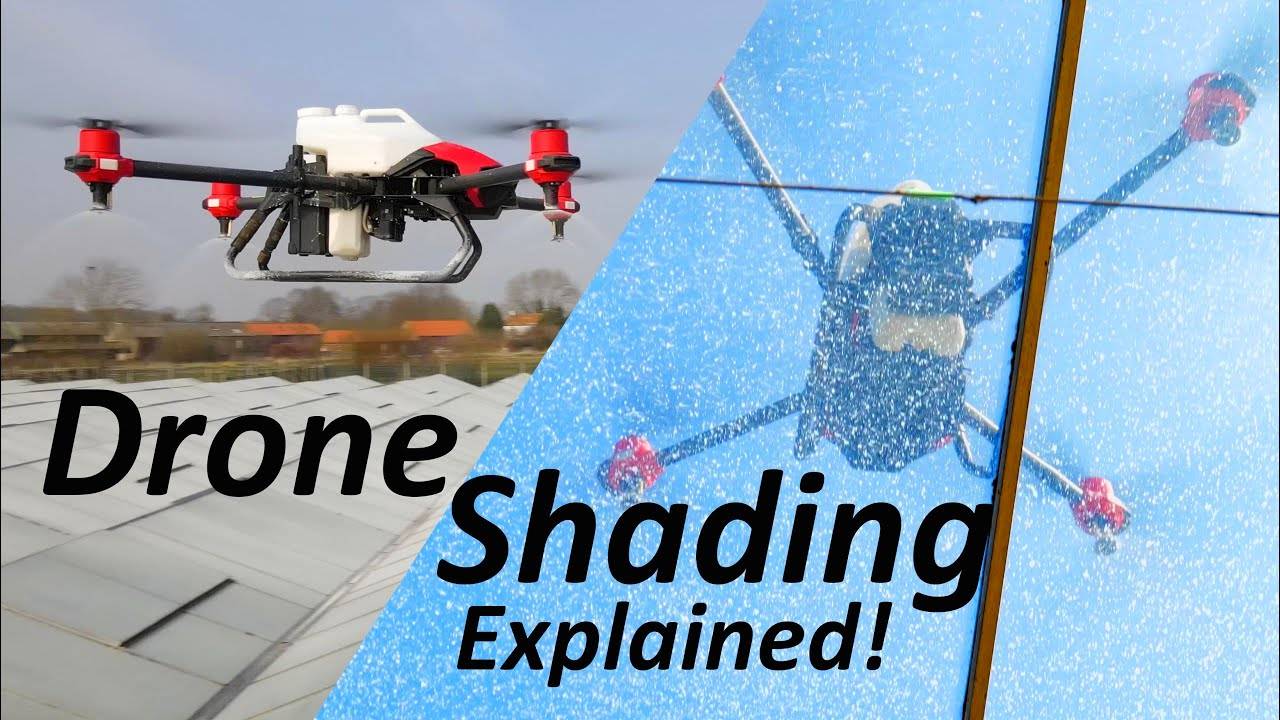

Coletta & Tyson Nurseries, one of Europe’s largest growers, needed to apply a specialised Q4 shading agent across their vast, multi-site operation totaling 26 hectares of greenhouses. The traditional method of manual application requires personnel to balance on gutters, dragging heavy hoses, which is highly dangerous. They needed a high-capacity, safe, and precise method that could handle the thicker, suspension-based shading liquid without blocking nozzles.

Solution

CDA Technology and Streamlined Logistics

AutoSpray Systems deployed the XAG drone to apply the Q4 shading agent at an application rate of 600 litres per hectare. The solution hinged on the drone’s Controlled Droplet Applicator (CDA) technology, which is designed specifically to prevent blocking, even when spraying thick suspension liquids like paint. The project prioritised safety, restricting the take-off/landing area to ground crew only. The high-output charging system, capable of recharging batteries in 10 minutes, allowed for smooth, back-to-back flights.

Result

Safety, Speed, and Optimised Crop Conditions

The drone application proved to be dramatically safer and more efficient than manual methods. Critically, the system allowed for layered shading—applying two coats to main production areas to optimise conditions. This layerability helped optimise growing conditions in different zones of the glasshouse. The use of the drone resulted in the shading being completed in half the time and using half the usual amount of shading agent, while eliminating the high-risk manual work.

- Greenhouse area shaded across 14 locations 26 Hectares

- Compared with traditional methods Half the Time

- Compared with traditional methods Half the Product

- Litres per hectare 600

Project Partners